Description of "DAIWA 2020 ALPHAS AIR TW 8.6R "

Winding length: 75cm/per handle rotation Gear ratio: 8.6 Weight: 160g Maximum Drag force: 3.5kg Line Capacity Fluoro: 6lb-45m, 8lb-45m Handle length: 80mm Spool diameter: 28mm Bearing (ball/roller): 6/1 A bait finesse machine with a strong aluminum body. A new standard bait finesse machine that can be used not only in freshwater but also in seawater ■ALPHAS is finally reborn with the TWS system. Equipped with a small diameter φ28mm G1 duralumin AIR spool to achieve a new dimension of finesse performance. Salt-compatible specifications that enable not only bass fishing but also trout in mountain streams, as well as bait finesse games with salt. The body consists of a full aluminum housing and was developed with various light game fishing in mind.

Technology Features of DAIWA 2020 ALPHAS AIR TW 8.6R

TWS (T-Wing System)

Traditional level wind systems were designed, as their name suggests, to lay the line evenly across the spool. However, during casting, they often created resistance, leading manufacturers to experiment with different internal diameters and shapes to enhance line release. But these efforts had their limits. Excessive enlargement of the level wind compromised its original function, restricting advancements to minimal adjustments, such as refining the internal diameter. Some solutions included increasing the distance between the spool and the level wind or narrowing the spool width to prevent the line from hitting the level wind at sharp angles. While partially effective, these methods were essentially temporary fixes that led to side effects such as elongating the reel body, reducing palming comfort, or decreasing line capacity.

DAIWA's TWS (T-Wing System) addresses these contradictions not with compromise but with innovation, achieving both precise line winding and an expanded resistance-free range during line release. By significantly widening the resistance-free zone where the line makes contact with the level wind, particularly right after it leaves the spool, TWS has dramatically enhanced the long-casting performance of DAIWA baitcasting reels. Simultaneously, the smooth line flow facilitated by TWS has proven effective in preventing backlashes.

UTD (Baitcasting)

By re-evaluating the washers and grease from the ground up, DAIWA has refined the drag system to reduce initial resistance when a fish is hooked, ensuring the line starts to slip smoothly and consistently. This advanced drag system, which surpasses the previously established standards set by DAIWA, is designated as "UTD" (Ultimate Tournament Drag).

ULTIMATE CASTING BRAKE

DAIWA was the first in the world to apply the principles of magnetism and electromagnetism to control the spool rotation in baitcasting reels. After over forty years of continuous refinement, the ULTIMATE CASTING BRAKE was born, characterized by two key elements. First, it employs a non-contact, electromagnetic induction brake system called “MAGFORCE”, which generates braking force without relying on friction. Second, it features a [Variable Induct Rotor] that adjusts the braking force according to the spool's rotational speed, ensuring optimal control based on the angler's input and the lure's flight.

The ULTIMATE CASTING BRAKE's non-contact design offers significant advantages, such as resistance to water, rain, splashes, and humidity, while its parts remain free from wear, resulting in consistently stable performance that lasts nearly indefinitely. The stable performance of MAGFORCE allows the Variable Induct Rotor to be finely tuned for various scenarios, such as improving compatibility with lightweight lures, enhancing versatility, and enabling exceptional long-distance casting through its dual-stage Variable Induct Rotor.

ZERO ADJUST

Since 2016, DAIWA has referred to the mechanical brake as the Zero Adjuster. This change was prompted by the evolution of DAIWA's baitcasting reels, where the primary brake system, MAGFORCE, reached its pinnacle, rendering the secondary mechanical brake unnecessary for braking purposes. Instead of functioning as a brake, the mechanical brake now serves solely to set the spool shaft's lateral movement within an optimal range (less than 0.2mm). By eliminating the complexity and ambiguity of using a secondary brake, the ZERO ADJUST system ensures complete spool control with just the main brake.

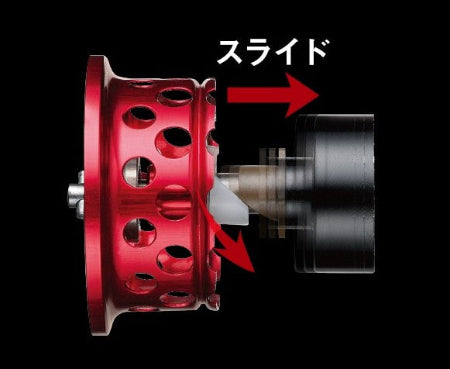

AIR BRAKE SYSTEM

The AIR BRAKE SYSTEM significantly enhances casting accuracy while minimizing the risk of backlash, providing a stress-free experience. During full casts, the brake engages effectively, but in low-speed operations like pitching, the inductor rotor remains retracted, reducing the braking force. This system allows for low-trajectory casting and seamlessly balances pitching and casting at a high level.

G1 DURALUMIN SPOOL

G1 Duralumin is an advanced aluminum alloy that boasts twice the strength of magnesium and is 1.3 times stronger than super-duralumin. Known for being extremely lightweight, this material is also highly rigid, making it the top choice among lightweight alloys used in aircraft structures and precision instruments. To achieve an exceptionally lightweight feel without compromising strength, the winding surface of the spool has been thinned without any blanking in material, preserving its full strength. The result is unmatched rotational responsiveness due to its lightness and highly precise rotation thanks to its superior rigidity.

ZERO SHAFT

Typically, spools are supported by a shaft integrated with the spool itself, but with ZERO SHAFT, the spool is supported solely by ball bearings. By eliminating the shaft, unnecessary resistance is removed, resulting in optimal spool rotation. This feature prioritizes casting performance, making it a crucial element of the stress free casting. Previously known as the Speed Shaft, this spool mechanism was renamed "ZERO SHAFT" in 2021.

Daiwa 2020 Alphas Air TW Spec Chart

Daiwa 2020 Alphas Air TW Line-up

| Line-up | Handle | Year | Salt or Fresh | Weight(g) | Gear Ratio | Retrieve(cm/crank) | Max Drag(kg) | Mono line cap. (lb-m) | Spool diameter (mm) | Spool width (mm) | Handle Arm(mm) | Bearing (Ball/Roller) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7.1R | Right | 2020 | Saltwater OK | 160 | 7.1 | 62 | 3.5 | 6-45, 8-45 | 28 | 21 | 80 | 6/1 |

| 7.1L | Left | 2020 | Saltwater OK | 160 | 7.1 | 62 | 3.5 | 6-45, 8-45 | 28 | 21 | 80 | 6/1 |

| 8.6R | Right | 2020 | Saltwater OK | 160 | 8.6 | 75 | 3.5 | 6-45, 8-45 | 28 | 21 | 80 | 6/1 |

| 8.6L | Left | 2020 | Saltwater OK | 160 | 8.6 | 75 | 3.5 | 6-45, 8-45 | 28 | 21 | 80 | 6/1 |

Specifications in Pound-Yard Notation

| Line-up | Handle | Year | Salt or Fresh | Weight(oz) | Gear Ratio | Retrieve(in/crank) | Max Drag(lb) | Mono line cap. (lb-yd) | Spool diameter (in) | Spool width (in) | Handle Arm(in) | Bearing (Ball/Roller) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7.1R | Right | 2020 | Saltwater OK | 5.7 | 7.1 | 24.4 | 7.8 | 6-50, 8-50 | 1.1 | 0.83 | 3.15 | 6/1 |

| 7.1L | Left | 2020 | Saltwater OK | 5.7 | 7.1 | 24.4 | 7.8 | 6-50, 8-50 | 1.1 | 0.83 | 3.15 | 6/1 |

| 8.6R | Right | 2020 | Saltwater OK | 5.7 | 8.6 | 29.5 | 7.8 | 6-50, 8-50 | 1.1 | 0.83 | 3.15 | 6/1 |

| 8.6L | Left | 2020 | Saltwater OK | 5.7 | 8.6 | 29.5 | 7.8 | 6-50, 8-50 | 1.1 | 0.83 | 3.15 | 6/1 |