Description of "DAIWA 2024 STEEZ SV TW 100L"

Weight: 160g Winding length: 67cm/per handle rotation Gear ratio: 6.7 Line Capacity Fluorocarbon: 12lb-40~80m Handle length: 85mm Bearing quantity BB/Roller: 12/1 Maximum drag force: 5kg Handle knob: HG-I shape light knob Third generation Steez launched. Steez bait reels are available in 2mm diameter increments. 28mm (AIR), 30mm (CT), 34mm (Limited A2), 36mm (HLC). The versatile Φ32mm hole that has been open for a long time in the middle. The masterpiece that completes the picture of next-generation bait strategy is the 3rd generation Steez SV TW equipped with a 32mm SV Boost spool. This third generation does not have a zero adjuster. As of the second generation, the brake adjustment of the reel was already completed using only the Mag Force dial. The third generation completely removes the mechanism that used to be called a mechanical brake and has been reborn with a new sub-brakeless structure. Hyper Drive Design is installed in a highly rigid and compact housing. The G1 duralumin 32mm SV Boost spool, TWS, and sub-brakeless mechanisms comply with the Ultimate Casting Design, a casting design concept that Daiwa has pursued for many years and finally completed.

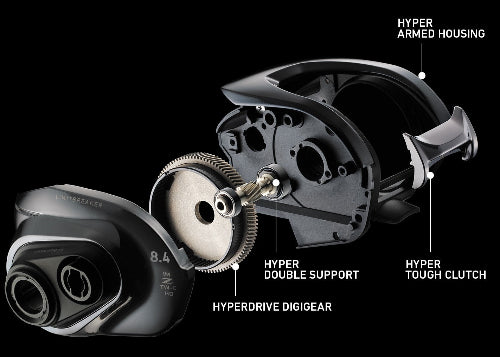

Technology Features of DAIWA 2024 STEEZ SV TW 100L

HYPERDRIVE DESIGN

In 2021, DAIWA’s new baitcasting reels underwent a significant evolution, marking a new era of innovation. The term that embodies this transformation is "HYPERDRIVE DESIGN." This new design philosophy aims to elevate all basic performance levels, ensuring they remain consistently high over time. At its core is the HYPERDRIVE DIGIGEAR, which includes both the drive and pinion gears. Supporting this are three additional key components: HYPER DOUBLE SUPPORT (pinion gear support system), HYPER ARMED HOUSING (reel body), and HYPER TOUGH CLUTCH. These four critical elements, refined with DAIWA's cutting-edge technology and new innovations, collectively deliver exceptional drive performance. A model featuring HYPERDRIVE DIGIGEAR and enhanced rotational performance falls under the HYPERDRIVE DESIGN category.

HYPERDRIVE DIGIGEAR

HYPERDRIVE DIGIGEAR is a newly designed gear system for baitcasting and conventional reels, engineered to maintain strong and smooth rotation over time. DAIWA’s unique technology avoids reducing the module size of the gear teeth, which is crucial for durability. Instead, it enhances meshing efficiency by shaping the gear teeth with a bullet-shaped silhouette that optimizes the pressure angle. This design ensures the initial smoothness of the reel lasts longer, achieving an exceptional balance between smooth rotation and rotational durability. Compared to previous DAIWA gears, the noise felt during handle rotation, such as roughness, has been significantly reduced by over 50% in the HYPERDRIVE DIGIGEAR.

HYPER DOUBLE SUPPORT

The HYPER DOUBLE SUPPORT system is a pinion gear support mechanism that enhances smoothness, power, and lightness in the reel’s operation. By precisely supporting both ends of the pinion gear with two ball bearings, it ensures that the power input from the handle is transmitted without loss, allowing for powerful and light winding even under load. The pinion gear, a crucial component on par with the drive gear in baitcasting reels, has also undergone significant evolution. Like the drive gear, the pinion gear’s tooth surface has been updated with new specifications, and the use of special materials has greatly reduced issues such as corrosion, seizing, and damage, thereby significantly contributing to the gear's durability.

HYPER ARMED HOUSING

The HYPER ARMED HOUSING is a body system designed to provide high rigidity and precision, supporting the internal structure of the reel to deliver smooth winding and power. A key requirement is the use of metal materials for the frame, which, when combined with side plates and set plates, ensures that the reel's fundamental performance is maintained over an extended period.

HYPER TOUGH CLUTCH

The HYPER TOUGH CLUTCH system delivers precise on/off performance, maintaining its reliability through thousands of cycles. It is designed to be highly durable, even in saltwater environments with high salt concentrations. Featuring an advanced insulation structure, this system has achieved a 99% reduction in sticking-related repairs compared to DAIWA's previous clutch systems, showcasing its exceptional performance in harsh conditions.

TWS (T-Wing System)

Traditional level wind systems were designed, as their name suggests, to lay the line evenly across the spool. However, during casting, they often created resistance, leading manufacturers to experiment with different internal diameters and shapes to enhance line release. But these efforts had their limits. Excessive enlargement of the level wind compromised its original function, restricting advancements to minimal adjustments, such as refining the internal diameter. Some solutions included increasing the distance between the spool and the level wind or narrowing the spool width to prevent the line from hitting the level wind at sharp angles. While partially effective, these methods were essentially temporary fixes that led to side effects such as elongating the reel body, reducing palming comfort, or decreasing line capacity.

DAIWA's TWS (T-Wing System) addresses these contradictions not with compromise but with innovation, achieving both precise line winding and an expanded resistance-free range during line release. By significantly widening the resistance-free zone where the line makes contact with the level wind, particularly right after it leaves the spool, TWS has dramatically enhanced the long-casting performance of DAIWA baitcasting reels. Simultaneously, the smooth line flow facilitated by TWS has proven effective in preventing backlashes.

ULTIMATE CASTING DESIGN

In 1982, DAIWA pioneered the development of the electromagnetic induction brake system known as “MAGFORCE”. Over forty years have passed since then, and during this time, DAIWA has relentlessly refined the performance of MAGFORCE, the main braking system, ultimately reaching the pinnacle of casting design—eliminating the need for a secondary (mechanical) brake altogether.

Key to this achievement are several innovative technologies: the “Variable Induct Rotor”, which determines the braking characteristics anglers demand, such as versatility, long-distance casting, and finesse performance; the “TWS”, which dramatically enhances casting distance and trouble-free performance; the top-grade, high-strength special aluminum alloy, “G1 Duralumin”, essential for low-inertia spools; and “ZERO Adjust”, which frees anglers from the hassle of mechanical brake settings and contact resistance. Together, these cutting-edge technologies form DAIWA's casting philosophy, enabling anglers to cast further and more accurately.

ULTIMATE CASTING BRAKE

DAIWA was the first in the world to apply the principles of magnetism and electromagnetism to control the spool rotation in baitcasting reels. After over forty years of continuous refinement, the ULTIMATE CASTING BRAKE was born, characterized by two key elements. First, it employs a non-contact, electromagnetic induction brake system called “MAGFORCE”, which generates braking force without relying on friction. Second, it features a [Variable Induct Rotor] that adjusts the braking force according to the spool's rotational speed, ensuring optimal control based on the angler's input and the lure's flight.

The ULTIMATE CASTING BRAKE's non-contact design offers significant advantages, such as resistance to water, rain, splashes, and humidity, while its parts remain free from wear, resulting in consistently stable performance that lasts nearly indefinitely. The stable performance of MAGFORCE allows the Variable Induct Rotor to be finely tuned for various scenarios, such as improving compatibility with lightweight lures, enhancing versatility, and enabling exceptional long-distance casting through its dual-stage Variable Induct Rotor.

ZERO ADJUST

Since 2016, DAIWA has referred to the mechanical brake as the Zero Adjuster. This change was prompted by the evolution of DAIWA's baitcasting reels, where the primary brake system, MAGFORCE, reached its pinnacle, rendering the secondary mechanical brake unnecessary for braking purposes. Instead of functioning as a brake, the mechanical brake now serves solely to set the spool shaft's lateral movement within an optimal range (less than 0.2mm). By eliminating the complexity and ambiguity of using a secondary brake, the ZERO ADJUST system ensures complete spool control with just the main brake.

ULTIMATE CASTING SPOOL

The ULTIMATE CASTING SPOOL is a high-strength, low-inertia spool crafted using advanced materials and machining techniques. While aluminum alloys are commonly used for baitcasting reel spools, DAIWA’s choice of G1 Duralumin represents the pinnacle of strength and quality. This material boasts twice the strength of magnesium and 1.3 times the strength of super duralumin. When designed with strength as a priority, G1 Duralumin allows for an exceptionally lightweight spool.

However, achieving such high precision with G1 Duralumin requires advanced machining techniques. The ability to design and process this material into ultra-thin components is essential for harnessing its rigidity in creating a lightweight spool.

DAIWA’s high-strength, low-inertia spools, with G1 Duralumin at the top, are known for their quick rotational start-up during casting and extremely responsive braking. This low-inertia spool is crucial in allowing the MAGFORCE braking system to express its characteristics across four categories: [SV - Super Versatile], [BF - Bait Finesse], [LC - Long Cast], and [IM - Intelligent Magforce].

SV BOOST

SV BOOST enhances the exceptional, stress-free performance of the SV spool, allowing anglers to handle any lure and any situation with ease, while significantly improving long-distance casting performance. By evolving the previously single-stage induct rotor into a two-stage variable system, SV BOOST achieves greater casting distance across both high and low spool rotations, maintaining the trouble-free characteristics of the SV system. Distance tests have shown a 4% increase in casting distance compared to conventional SV spools, with extended reach particularly noticeable in the latter part of the cast.

G1 DURALUMIN SPOOL

G1 Duralumin is an advanced aluminum alloy that boasts twice the strength of magnesium and is 1.3 times stronger than super-duralumin. Known for being extremely lightweight, this material is also highly rigid, making it the top choice among lightweight alloys used in aircraft structures and precision instruments. To achieve an exceptionally lightweight feel without compromising strength, the winding surface of the spool has been thinned without any blanking in material, preserving its full strength. The result is unmatched rotational responsiveness due to its lightness and highly precise rotation thanks to its superior rigidity.

ZERO SHAFT

Typically, spools are supported by a shaft integrated with the spool itself, but with ZERO SHAFT, the spool is supported solely by ball bearings. By eliminating the shaft, unnecessary resistance is removed, resulting in optimal spool rotation. This feature prioritizes casting performance, making it a crucial element of the stress free casting. Previously known as the Speed Shaft, this spool mechanism was renamed "ZERO SHAFT" in 2021.

UTD (Baitcasting)

By re-evaluating the washers and grease from the ground up, DAIWA has refined the drag system to reduce initial resistance when a fish is hooked, ensuring the line starts to slip smoothly and consistently. This advanced drag system, which surpasses the previously established standards set by DAIWA, is designated as "UTD" (Ultimate Tournament Drag).

Daiwa 2024 Steez SV TW Spec Chart

Daiwa 2024 Steez SV TW Line-up

| Line-up | Handle | Year | Salt or Fresh | Weight(g) | Gear Ratio | Retrieve(cm/crank) | Max Drag(kg) | Mono line cap. (lb-m) | Braided line cap. (lb-m) | Spool diameter (mm) | Spool width (mm) | Handle Arm(mm) | Bearing (Ball/Roller) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | Right | 2024 | Saltwater OK | 160 | 6.7 | 67 | 5 | 12-40~80, 14-35~70 | 30-120, 40-100 | 32 | 22.5 | 85 | 12/1 |

| 100L | Left | 2024 | Saltwater OK | 160 | 6.7 | 67 | 5 | 12-40~80, 14-35~70 | 30-120, 40-100 | 32 | 22.5 | 85 | 12/1 |

| 100H | Right | 2024 | Saltwater OK | 160 | 7.8 | 78 | 5 | 12-40~80, 14-35~70 | 30-120, 40-100 | 32 | 22.5 | 85 | 12/1 |

| 100HL | Left | 2024 | Saltwater OK | 160 | 7.8 | 78 | 5 | 12-40~80, 14-35~70 | 30-120, 40-100 | 32 | 22.5 | 85 | 12/1 |

| 100XH | Right | 2024 | Saltwater OK | 160 | 8.5 | 85 | 5 | 12-40~80, 14-35~70 | 30-120, 40-100 | 32 | 22.5 | 85 | 12/1 |

| 100XHL | Left | 2024 | Saltwater OK | 160 | 8.5 | 85 | 5 | 12-40~80, 14-35~70 | 30-120, 40-100 | 32 | 22.5 | 85 | 12/1 |

Specifications in Pound-Yard Notation

| Line-up | Handle | Year | Salt or Fresh | Weight(oz) | Gear Ratio | Retrieve(in/crank) | Max Drag(lb) | Mono line cap. (lb-yd) | Braided line cap. (lb-yd) | Spool diameter (in) | Spool width (in) | Handle Arm(in) | Bearing (Ball/Roller) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | Right | 2024 | Saltwater OK | 5.7 | 6.7 | 26.4 | 11.1 | 12-45~90, 14-40~80 | 30-130, 40-110 | 1.26 | 0.89 | 3.35 | 12/1 |

| 100L | Left | 2024 | Saltwater OK | 5.7 | 6.7 | 26.4 | 11.1 | 12-45~90, 14-40~80 | 30-130, 40-110 | 1.26 | 0.89 | 3.35 | 12/1 |

| 100H | Right | 2024 | Saltwater OK | 5.7 | 7.8 | 30.7 | 11.1 | 12-45~90, 14-40~80 | 30-130, 40-110 | 1.26 | 0.89 | 3.35 | 12/1 |

| 100HL | Left | 2024 | Saltwater OK | 5.7 | 7.8 | 30.7 | 11.1 | 12-45~90, 14-40~80 | 30-130, 40-110 | 1.26 | 0.89 | 3.35 | 12/1 |

| 100XH | Right | 2024 | Saltwater OK | 5.7 | 8.5 | 33.5 | 11.1 | 12-45~90, 14-40~80 | 30-130, 40-110 | 1.26 | 0.89 | 3.35 | 12/1 |

| 100XHL | Left | 2024 | Saltwater OK | 5.7 | 8.5 | 33.5 | 11.1 | 12-45~90, 14-40~80 | 30-130, 40-110 | 1.26 | 0.89 | 3.35 | 12/1 |