Description of "DAIWA 2024 CERTATE LT5000D-CXH"

Marca: DAIWA

Peso: 245(g)=8,75(oz)

Relación de transmisión: 6,2:1

Fuerza de arrastre máxima: 12 (kg) = 26,7 (lb)

Capacidad de línea de nailon (lb-yd): 25-165

Capacidad de trenza (lb-yd): 50-330

Longitud de recuperación: 105 (cm) = 41,3 (pulg.)

Longitud del mango: 60 (mm) = 2,36 (pulg.)

Rodamientos (Bolas/Rodillos): 10/1

Technology Features of DAIWA 2024 CERTATE LT5000D-CXH

AIRDRIVE DESIGN

AIRDRIVE DESIGN is the next-generation spinning reel concept, developed to allow anglers to control lures with precision and ease. This design is composed of up to four advanced technologies. At its core is the AIRDRIVE ROTOR, which ensures smooth and highly responsive rotation, making it an essential component. Supporting this performance are the AIRDRIVE BAIL, which is lightweight and trouble-free, and the AIRDRIVE SPOOL, which has been meticulously engineered to reduce unnecessary material to the absolute minimum, achieving an extremely lightweight design. Finally, the AIRDRIVE SHAFT, supported by high-precision collars and featuring a non-contact structure with the pinion gear, enables exceptionally smooth winding with minimal noise, even under heavy loads. The synergy of these elements, along with improved reel balance, delivers superior operability at a high level.

AIRDRIVE ROTOR (ZAION)

DAIWA has continuously focused on improving the rotational response of spinning reel rotors. Through its unique approach, DAIWA has developed a new shape that appears to be carved directly from a sphere. By reinforcing areas where stress concentrates and thoroughly eliminating unnecessary material in less critical areas, they have achieved significant weight reduction while maintaining rigidity. This innovation has drastically improved the ease of rotation, leading to enhanced operability and sensitivity.

AIRDRIVE BAIL

For many years, DAIWA's spinning reels have featured the Air Bail, utilizing a hollow pipe structure that provides both lightness and rigidity. This design, along with its unique shape, ensures that the line is smoothly guided to the line roller, minimizing trouble during retrieval. The AIRDRIVE BAIL further enhances this by achieving even greater weight reduction while maintaining necessary strength through a slimmer design. Additionally, the bail is angled optimally to allow the line to transition more smoothly from the bail to the line roller, supporting the performance of the AIRDRIVE ROTOR while becoming even lighter and more trouble-free.

To achieve effortless line pickup, where the line is automatically set on the line roller via the bail, the bail's tilt angle is meticulously adjusted. The angle is made more obtuse as the line approaches the line roller, making it easier to guide the line to the roller.

In the AIRDRIVE BAIL, DAIWA offers a wire-type option that adopts a solid structure instead of adhering to the hollow pipe design. This wire type maintains sufficient strength for practical fishing while also achieving significant weight reduction and greatly reducing line troubles compared to conventional wire bails. The wire-type bail features an adjusted tilt angle, redesigned arm lever and line slider shapes, and an "anti-tangle roof" installed above the line roller, effectively preventing line tangles.

AIRDRIVE SPOOL

The AIRDRIVE SPOOL is designed with an ultra-thin construction, meticulously engineered to eliminate unnecessary material while maintaining strength. This lightweight design extends not only to the line-winding area and spool skirt but also to the interior of the spool, where no compromises were made. The reduction in spool weight enhances the ease of rotation, casting performance, and overall operability. Additionally, a new drag sound mechanism with minimal operational resistance has been developed. This mechanism produces a pleasant clicking sound while reducing resistance during operation, ensuring smoother and more consistent drag performance without any sticking.

AIRDRIVE SHAFT

DAIWA's linear shaft system, featured in its spinning reels, eliminates frictional resistance by creating a non-contact structure between the main shaft and the pinion gear. The AIRDRIVE SHAFT further enhances this by supporting both ends of the pinion gear with ball bearings, maximizing the power transferred from the handle to the rotor's rotational force. Additionally, the main shaft is supported by high-precision collars, which significantly reduce rotational noise.

MONOCOQUE BODY (Aluminum)

The MONOCOQUE BODY in DAIWA reels refers to a single-piece body structure. Traditional spinning reels covered the drive gear with a body and body cover, secured by several screws, which posed strength issues. The MONOCOQUE BODY eliminates the body cover, directly setting a high-precision plate into the body. This change supports the body with the entire plate surface instead of just screw points, significantly enhancing precision, rigidity, and sealing. Also, because the fixed part of the screw that occupied space inside the body has been removed, It allows for larger drive gears, providing more powerful retrieves and smoother fights with big fish.

MAGSEALED

DAIWA's MAGSEALED technology is designed to prevent water, salt, and debris from entering the reel, using magnetic fluid to form a barrier that protects critical components like bearings, line rollers, and gears from saltwater. DAIWA adapted magnetic fluid technology initially developed by NASA for dust protection in hard drives used in space. Unlike traditional rubber seals that increase handle rotation friction, the magnetic fluid is held in place by a magnetic field, reducing friction and enabling smooth operation. This technology enhances the reel's durability and performance, significantly improving reliability in harsh fishing environments without requiring meticulous maintenance.

MAGSEALED LINE ROLLER

The line roller directly encounters water and sand carried by the line, making its waterproofing crucial for maintaining initial performance such as rotational feel and sensitivity. The MAGSEALED LINE ROLLER significantly reduces the ingress of salt and foreign particles. Additionally, improved rotation enhances the effectiveness of reducing line twist.

TOUGH DIGIGEAR (Super Duralumin)

DAIWA’s DIGIGEAR is a gear system realized through a manufacturing technique that accurately shapes the form derived from numerical analysis of power transmission efficiency by computer. Instead of casting, the gears are processed using forging, which provides higher strength, and then the gear teeth surfaces are smoothed through ultra-precision machine cutting, allowing for efficient power transmission. TOUGH DIGIGEAR enhances this by increasing the surface area of the gear teeth and the radius of the gear, further improving durability and strength, resulting in a smoother winding experience.

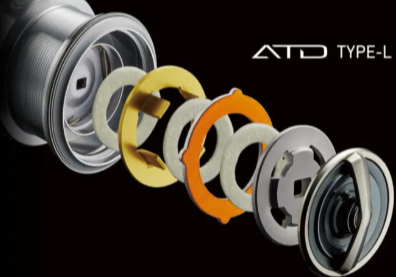

ATD TYPE-L

DAIWA’'s ATD (Automatic Drag) technology is an innovative system designed to address the issues found in traditional drag systems. Previously, the main problem was the lack of smoothness when the drag first engaged. ATD ensures a smooth initial drag, releasing lines with consistent tension under strong pressure, and offering gradual resistance under lighter pressure. This adaptability reduces the need for frequent adjustments of drag force and also improves hooking rates. Enhanced drag washers maintain drag strength during long fights, giving anglers an advantage against large fish. ATD provides a stress-free and efficient fishing experience.

ATD TYPE-L is designed to reduce the sudden spike in drag pressure when the line is pulled quickly, such as during a hookset, compared to the standard ATD. While maintaining the characteristics of ATD, ATD TYPE-L further improves the initial drag response, making it ideal for preventing line breaks when using light lines.

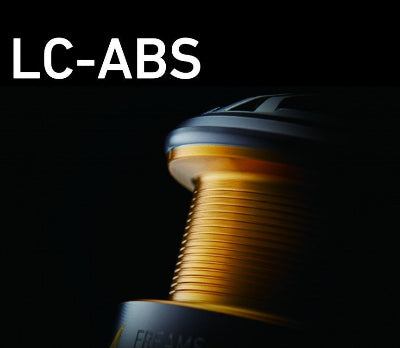

LC-ABS

The LC-ABS spool features a two-step design on the front edge to enhance line release performance and streamline the flow. While maintaining the trouble-free usage of the previous ABS spool, it achieves an approximate 5% increase in casting distance combined with a reduction in spool weight.

Daiwa 2024 Certate Spec Chart

Daiwa 2024 Certate Line-up

| Line-up | Year | Salt or Fresh | Weight(g) | Gear Ratio | Retrieve(cm/crank) | Max Drag(kg) | Mono line cap. (lb-m) | Braided line cap. (lb-m) | Handle Arm(mm) | Bearing (Ball/Roller) | Handle knob shape |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FC LT2000S-P | 2024 | Saltwater OK | 170 | 4.9 | 64 | 5 | 3-150 | 8-200 | 40 | 10/1 | I |

| FC LT2000S-H | 2024 | Saltwater OK | 170 | 5.8 | 76 | 5 | 3-150 | 8-200 | 45 | 10/1 | I |

| FC LT2500S | 2024 | Saltwater OK | 175 | 5.1 | 72 | 5 | 4-150 | 12-200 | 50 | 10/1 | I |

| FC LT2500S-XH | 2024 | Saltwater OK | 175 | 6.2 | 87 | 5 | 4-150 | 12-200 | 50 | 10/1 | I |

| FC LT2500S-DH | 2024 | Saltwater OK | 185 | 5.1 | 72 | 5 | 4-150 | 12-200 | 90 | 10/1 | I |

| LT2500 | 2024 | Saltwater OK | 200 | 5.2 | 73 | 10 | 6-150 | 16-200 | 50 | 10/1 | T |

| LT2500-H | 2024 | Saltwater OK | 200 | 5.7 | 80 | 10 | 6-150 | 16-200 | 55 | 10/1 | T |

| LT3000-CH | 2024 | Saltwater OK | 205 | 5.7 | 85 | 10 | 8-150 | 20-200 | 55 | 10/1 | T |

| LT3000 | 2024 | Saltwater OK | 225 | 5.2 | 77 | 10 | 8-150 | 20-200 | 60 | 10/1 | T |

| LT3000-XH | 2024 | Saltwater OK | 225 | 6.2 | 93 | 10 | 8-150 | 20-200 | 60 | 10/1 | T |

| LT4000-C | 2024 | Saltwater OK | 235 | 5.2 | 82 | 12 | 12-150 | 30-200 | 60 | 10/1 | T |

| LT4000-CXH | 2024 | Saltwater OK | 235 | 6.2 | 99 | 12 | 12-150 | 30-200 | 60 | 10/1 | T |

| LT5000D-CXH | 2024 | Saltwater OK | 245 | 6.2 | 105 | 12 | 25-150 | 50-300 | 60 | 10/1 | Round |

| LT5000D | 2024 | Saltwater OK | 290 | 5.2 | 87 | 12 | 25-150 | 50-300 | 65 | 10/1 | Round |

| LT5000D-XH | 2024 | Saltwater OK | 290 | 6.2 | 105 | 12 | 25-150 | 50-300 | 65 | 10/1 | Round |

Specifications in Pound-Yard Notation

| Line-up | Year | Salt or Fresh | Weight(oz) | Gear Ratio | Retrieve(in/crank) | Max Drag(lb) | Mono line cap. (lb-yd) | Braided line cap. (lb-yd) | Handle Arm(in) | Bearing (Ball/Roller) | Handle knob shape |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FC LT2000S-P | 2024 | Saltwater OK | 6.1 | 4.9 | 25.2 | 11.1 | 3-165 | 8-220 | 1.57 | 10/1 | I |

| FC LT2000S-H | 2024 | Saltwater OK | 6.1 | 5.8 | 29.9 | 11.1 | 3-165 | 8-220 | 1.77 | 10/1 | I |

| FC LT2500S | 2024 | Saltwater OK | 6.3 | 5.1 | 28.3 | 11.1 | 4-165 | 12-220 | 1.97 | 10/1 | I |

| FC LT2500S-XH | 2024 | Saltwater OK | 6.3 | 6.2 | 34.3 | 11.1 | 4-165 | 12-220 | 1.97 | 10/1 | I |

| FC LT2500S-DH | 2024 | Saltwater OK | 6.6 | 5.1 | 28.3 | 11.1 | 4-165 | 12-220 | 3.54 | 10/1 | I |

| LT2500 | 2024 | Saltwater OK | 7.1 | 5.2 | 28.7 | 22.2 | 6-165 | 16-220 | 1.97 | 10/1 | T |

| LT2500-H | 2024 | Saltwater OK | 7.1 | 5.7 | 31.5 | 22.2 | 6-165 | 16-220 | 2.17 | 10/1 | T |

| LT3000-CH | 2024 | Saltwater OK | 7.3 | 5.7 | 33.5 | 22.2 | 8-165 | 20-220 | 2.17 | 10/1 | T |

| LT3000 | 2024 | Saltwater OK | 8 | 5.2 | 30.3 | 22.2 | 8-165 | 20-220 | 2.36 | 10/1 | T |

| LT3000-XH | 2024 | Saltwater OK | 8 | 6.2 | 36.6 | 22.2 | 8-165 | 20-220 | 2.36 | 10/1 | T |

| LT4000-C | 2024 | Saltwater OK | 8.4 | 5.2 | 32.3 | 26.7 | 12-165 | 30-220 | 2.36 | 10/1 | T |

| LT4000-CXH | 2024 | Saltwater OK | 8.4 | 6.2 | 39 | 26.7 | 12-165 | 30-220 | 2.36 | 10/1 | T |

| LT5000D-CXH | 2024 | Saltwater OK | 8.8 | 6.2 | 41.3 | 26.7 | 25-165 | 50-330 | 2.36 | 10/1 | Round |

| LT5000D | 2024 | Saltwater OK | 10.4 | 5.2 | 34.3 | 26.7 | 25-165 | 50-330 | 2.56 | 10/1 | Round |

| LT5000D-XH | 2024 | Saltwater OK | 10.4 | 6.2 | 41.3 | 26.7 | 25-165 | 50-330 | 2.56 | 10/1 | Round |